ULTRA SONIC NOZZLE ELECTRICALLY ACTUATED SPRAY NOZZLES

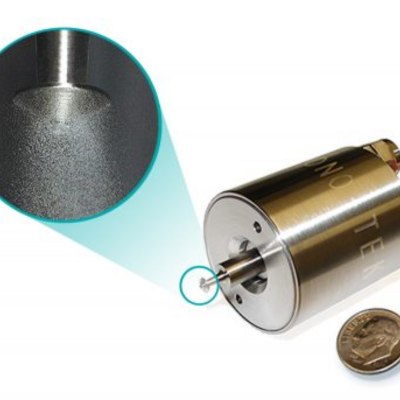

Ultrasonic nozzles operate by converting high frequency sound waves into mechanical energy that is transferred into a liquid, creating standing waves. As the liquid exits the atomizing surface of the nozzle, it is broken into a fine mist of uniform micron sized droplets. These nozzles are also known as Electrically actuated / controlled Spray Nozzles.

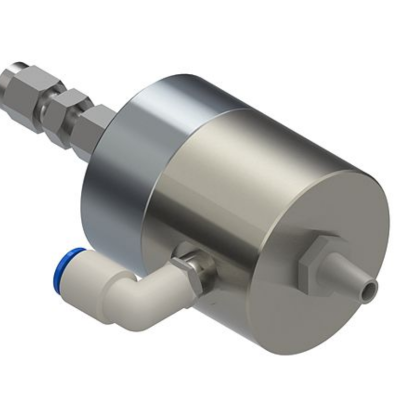

The electric hydro pulse nozzle has an integrated solenoid valve to rapidly regulate the on-off cycle of the nozzle. The solenoid valve is positioned inside the nozzle so that it is very close to the orifice. This means the reaction time of the shut off system is incredibly fast. The nozzle can be cycled off and on up to 150 times per second. Its used for precision spraying applications like tablet coating.

DETAILS

Every ultrasonic nozzle operates at a specific resonant frequency, which dictates the median droplet size. Droplet sizes have little variance, and can be mathematically calculated to fall within a tight predicted drop distribution. For example, a 120 kHz nozzle produces a median drop size of 18 microns (when spraying water). The higher the frequency, the smaller the median drop size.

Nozzles are fabricated from a very high-strength titanium alloy and other proprietary metals, making them exceptionally resistant to chemical attack and providing superior acoustical properties. The electrically active elements are contained within a sealed housing that protects the nozzle components from external contamination.